With more than one trillion barrels of discovered oil still in the ground, the need for improved oil recovery technology is compelling. Primera Resources is focused on improving oil and gas recovery from existing fields by bringing together leading technologies to improve water quality and injection, leading oil field chemicals and services to maximize oil recovery.

In order to appraise and design an advance EOR technique, a detailed understanding of field history, geology and physicochemical processes is required. An integrated study is essential to investigate pore-scale analysis, laboratory study and field-scale viability assessment.

Quickly and objectively evaluation of EOR potentials in complex reservoirs using EOR Geo-Screening, ensuring selected technology is the best fit for the reservoir.

Solutions

SCREENING or Prefeasibility

At Primera Resources, the EOR screening journey begins with method of choice. We believe every field has an optimal EOR scheme. Based on the characteristics of the field, an integrated approach is considered to evaluate the most suitable hydrocarbon extraction method (e.g. Thermal, Miscible, Chemical and Optimised water flooding).

It is important to embrace all filed traits and challenges and in order to tailor a solution best fit to the reservoir. The most suitable EOR technique for the selected reservoir is tailored by capitalising on our in-house the screening tools, which allow us to rank all the available EOR technique in an objective manner. Internal R&D results obtained by Primera Resources are continuously used to improve the software.

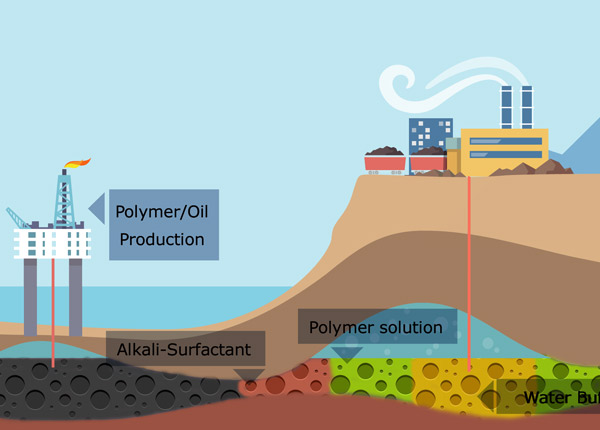

Laboratory investigation is used as part of screening process in chemical EOR to provide further details for optimal polymer, surfactant polymer (SP) or alkali surfactant polymer (ASP) design.

Laboratory

We believe it is of importance to embrace the candidate reservoir characteristics in order to design EOR processes. One way of accomplishing this is through laboratory analysis where fluid-fluid and rock-fluid interactions are evaluated. Doing so, we can introduce solutions tailored to each candidate reservoir.

Once an EOR technique is selected, the feasibility of the process for the candidate reservoir is evaluated and optimized at laboratory level. In order to ensure the effectiveness of the selected EOR technique ultimately at pilot and field scales, uncertainty and sensitivity analysis of parameter such as temperature, salinity, water quality and geological heterogeneity are carried out.

Here at Primera Resources, we provide comprehensive EOR laboratory services.

Our services are but not limited to:

- EOR Chemical Fluid analysis.

- Reservoir fluid analysis.

- Rock & Fluid interaction.

- Phase behavour studies.

- Core flooding.

- Test of EOR techniques under reservoir conditions.

- Evaluate the effect of injecting conformance controlling agents.

- Measure core porosity, permeability and wetability.

- Microfluid Chips .

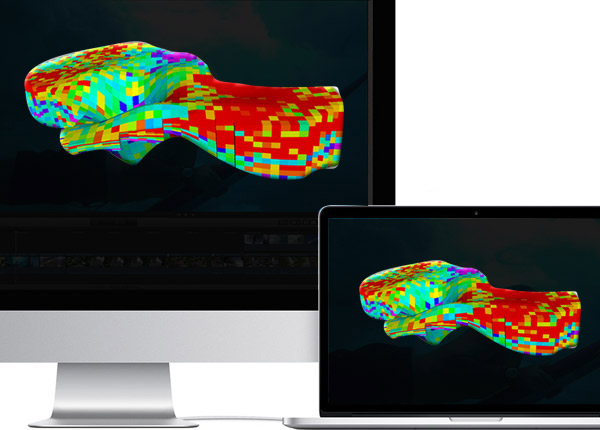

Simulation & Modelling

The EOR centre at Primera Resources offers full-scale reservoir simulation in relation to its services to the oil and gas industry. Our simulation services provide the oil and gas industry with a powerful tool to increase recovery, minimize risks and add low-cost barrels to existing production facilities.

- Modelling of enhanced oil recovery (EOR) in reservoir.

- Subsurface/Surface Software Setup for Conventional and Unconventional Studies.

- Field development and drilling plans.

- EOR field design and evaluation.

- EOR screening studies.

- Risk management and Uncertainty analysis.

- Pilot project design.

- Reservoir evaluation before and after EOR implementation.

- Reservoir performance monitoring.

- EOR field history matching.

Latest Projects

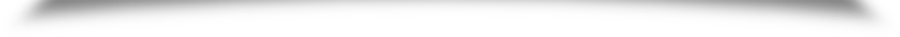

Feasibility Study on Offshore Polymer Flooding.

Forecasting Production through Integrated Asset Modelling, a Technical and Economic Approach.

Polymer flooding has been one of the emerging EOR techniques in offshore environment in the recent decades. The pilot implementation of polymer flooding has proved to be challenging due to the difficulties associated with the operational facilities and the high Capital Expenditure (CAPEX) required to initiate the project. Coupling the IAM technique to such project would provide valuable insight to the current and future field production levels and expected operating conditions.

The following work was a comprehensive review of offshore polymer flooding through Integrated Asset Modelling (IAM).

Top-end techniques from the subsurface/surface modelling point of view, using numerical reservoir simulation, in addition of IAM to model the complexity associated to subsurface and surface polymer flooding.

Experimental Design (ED) was used in this study in order to envisage the influence of all input variables on the outcome of the project.

Considering the current decline in the oil production rates in offshore fields in the North Sea, in order to preserve the present production levels, the polymer EOR infrastructure, facilities and technologies are considered as good areas of investment.

Subsequent to simulation findings, the liability of polymer flooding and associated incremental in terms of recovery was investigated at different oil prices.

Research & Development Studies

In collaboration with partners and Universities

Design, evaluation and numerical simulation of surfactant EOR under high salinity conditions.

The objective of this study was to evaluate and compare 6 commercial surfactants used in the process of core flooding at laboratory level with the view of obtaining incremental oil recovery. The study entailed a detailed examination on the physical and chemical interactions at fluid-fluid and fluid-rock levels whereby the effect of surfactant flooding, under high salinity levels, on the formation rock and fluid was analysed.

Investigate the effect of high salinity on the polymer viscosity in Heavy Oil Reservoir –From lab to full field simulation.

The scope of this study was to design a polymer flooding with the view of enhancing the oil recovery from core sample. The performance of 5 different KYPAM polymer solutions, all containing different molecular weights, were analyzed in laboratory conditions whereby the effect of high salinity, shear rate, concentration and temperature was intensively studied. The effect of the polymer solution on the core sample was then validated to design the simulation models.

Tailoring Surfactant Polymer flooding for an acidic and heavy crude oil under high salinity conditions.

The aim of this study was todesign an effective Surfactant–Polymer(SP)flooding for the purpose of incremental oil recovery of an acidic crude oil in a high salinity sandstone reservoir, and analyzing the interaction between crude oil, surfactant and polymer and also within the system rock and fluids. The study also included the study and evaluation of co-surfactants to enhance salinity tolerance.

Investigating the Effect of Salinity and Brine Composition on Alkaline, Surfactant Polymer Flooding.

The study was focused around the effect of brine composition and brine salinity by means of physical – chemical interactions between fluid-fluid and fluid-rock. This was accomplished by evaluating the influence of divalent ions Mg2+ and Ca2+ and salinity on the optimal properties of Alkaline, Surfactant and Polymer (ASP) flooding process.

Enhanced Oil Recovery

For more information related to this service please take a look to our service brouchure.

More Information

Strong focus on decision making and uncertainty analysis combined with advanced, state of the art and complex workflows.

Strong focus on decision making and uncertainty analysis combined with advanced, state of the art and complex workflows.